Rigid injection compounds offer remarkable properties and applications, and are poised for exciting future trends in material innovation.

Rigid compounds, particularly in the form of rigid injection compounds, have revolutionized various industries with their unique properties and versatile applications. These materials, known for their robustness and durability, are increasingly becoming the backbone of numerous manufacturing processes. This article delves into the properties of these compounds, their wide-ranging applications, and the future trends that are shaping their evolution.

Properties of Rigid Injection Compounds

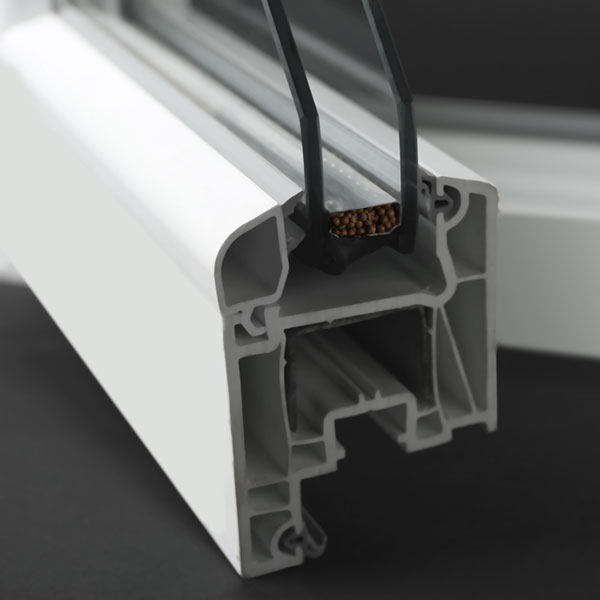

Rigid injection compounds are known for their high strength-to-weight ratio, making them an ideal choice for applications requiring durability without added bulk. They exhibit excellent dimensional stability, meaning they maintain their shape and size under a variety of environmental conditions. Additionally, these compounds often possess high resistance to chemicals, wear, and impact, which is crucial in harsh industrial environments. Their thermal stability is another key feature, allowing them to withstand high temperatures without degrading.

The versatility of these compounds is further enhanced by their ability to be customized through additives and fillers. This adaptability allows manufacturers to tailor the materials to specific requirements, such as improved UV resistance, flame retardancy, or electrical conductivity. Such customization opens the door to a broader range of applications, making rigid injection compounds a preferred choice in industries where material specifications are stringent and varied.

Applications in Various Industries

The applications of rigid injection compounds are diverse and span across multiple industries. In the automotive sector, they are used for manufacturing components that require high strength and durability, such as bumpers, dashboards, and various under-the-hood parts. In the field of medical devices, these compounds are utilized for creating surgical instruments and equipment housings that demand sterility and precision. The construction industry benefits from these materials in the form of sturdy, weather-resistant building components. Additionally, they are increasingly used in the electronics industry for creating robust casings and components that protect delicate electronic parts.

In consumer goods, rigid injection compounds are used in products ranging from household appliances to toys, showcasing their safety and reliability. The packaging industry also leverages these materials for creating durable and protective packaging solutions, particularly for sensitive or high-value items.

Future Trends for Rigid Injection Compounds

The future of rigid injection compounds is being shaped by ongoing research and development aimed at enhancing their properties and expanding their applications. One significant trend is the drive towards sustainability. Manufacturers are increasingly focusing on developing bio-based rigid compounds to reduce environmental impact.

Another trend is the integration of nanotechnology, which promises to further enhance the mechanical properties and functionality of these materials. Additionally, the growing demand for smart and functional materials is leading to the development of rigid injection compounds with integrated sensors and connectivity for use in the Internet of Things (IoT) applications.

Terraflex Industries: A Leader in Rigid Injection Compound Innovation

As we explore the future of rigid injection compounds, it’s essential to recognize the contributions of key industry players like Terraflex Industries. Terraflex, a leading manufacturer of extruded plastic products and PVC compounds, has been at the forefront of innovation in this field. Their commitment to quality and continuous improvement has made them a go-to source for high-performance rigid injection compounds.

With a focus on sustainability and technological advancement, Terraflex is not just keeping pace with the evolving demands of the industry but is also playing a pivotal role in shaping its future. As rigid injection compounds continue to evolve, companies like Terraflex are instrumental in driving the industry towards new horizons, offering materials that are not only effective but also environmentally responsible.